|

Modifier powder quasicrystalline

Quasicrystals is a new class of materials, with unique properties. NANOKOM has developed a unique technology that has reduced the cost of production to a level that provides the possibility of its application on an industrial scale.

Part number:

Supplier:

LLC "NANOCOM"Description

Modifier description

Quasicrystals is a new class of materials, discovered in 1984, with unique properties. Currently, a lot of research is being carried out in the world in the field of application of quasicrystals in almost all areas of industry. An obstacle to the large-scale practical application of quasicrystals is the high cost of synthesizing this material. NANOKOM has developed a unique technology that has reduced the cost of production to a level that provides the possibility of its application on an industrial scale.

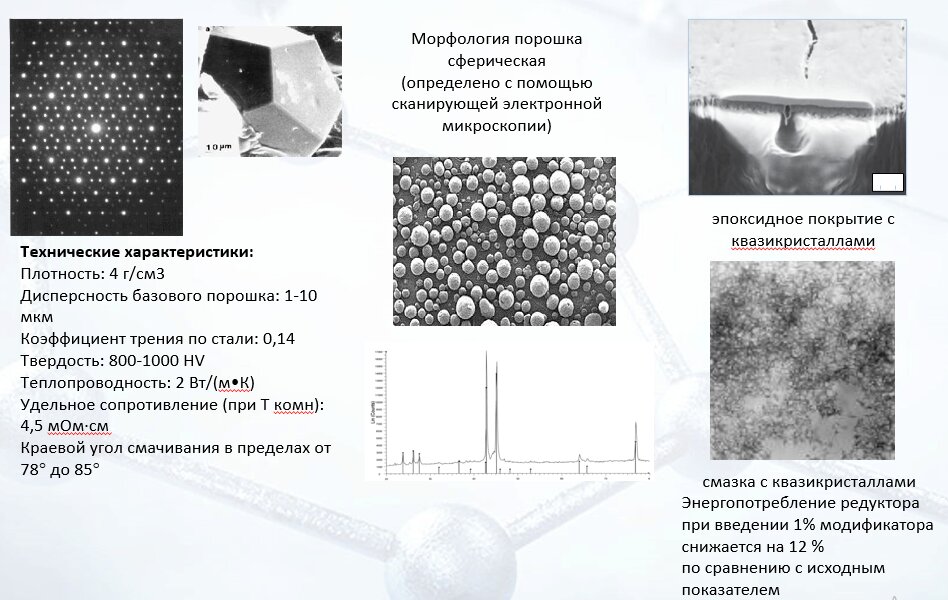

Specifications:

Density: 4 g / cm3

Dispersion of the base powder: 1-10 µm

Steel Friction Coefficient: 0.14

Hardness: 800-1000 HV

Thermal conductivity: 2 W / (m ∙ K)

Resistivity (at T room): 4.5 mOhm ∙ cm

Modifier assignment

1. Improving the mechanical characteristics and adhesion to metals of polymers, elastomers and materials based on them;

2. Decrease in friction, increase in energy efficiency and resource of friction units and mechanisms in normal working conditions, as well as in conditions of “oil starvation” and “dry friction”;

3. Increases wear resistance and abrasion in polytetrafluoroethylene (Teflon, PTFE, Fluoroplast-4) by 2 to 3 orders of magnitude;

4. Improving the physico-mechanical properties of babbits and increasing the life of products from babbits based on quasicrystals;

5. Reinforcing metals to create anti-friction composite materials;

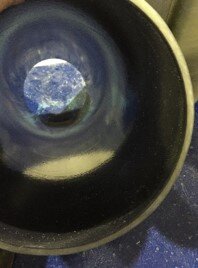

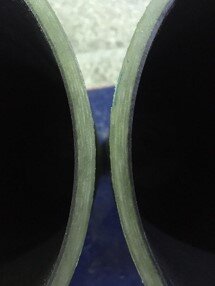

6. Formation of coatings on metals to reduce the coefficient of friction, as well as on glass to increase the level of hydrophobicity.

Modifier Application

In mechanical engineering, metallurgy and energy:

• Reduces friction losses and energy consumption, lowers temperature and noise of working mechanisms, increases the life of the mechanisms, prevents grasping and jamming of nodes and parts;

• Increases the service life of bearings, gears, transmissions when added to oil and grease;

• Increases the strength of polymer composite materials, plastic products.

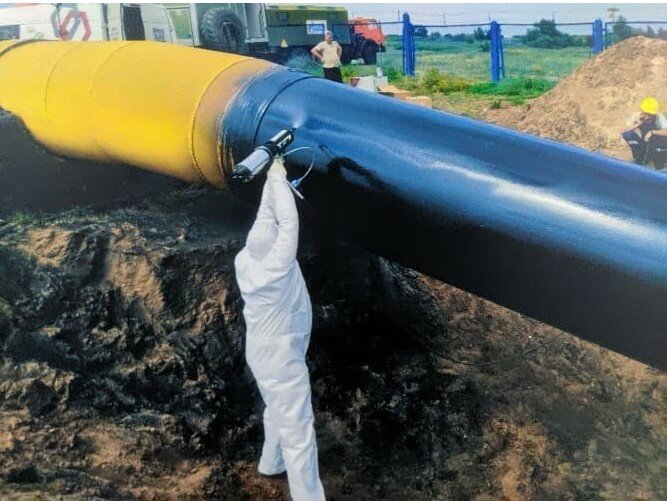

In oilfield services:

• Extends the life of rubber products, prevents peeling of rubber from metal;

• Increases the service life of rubbing units, reduces the coefficient of friction at the contact point in metal-metal and metal-rock pairs;

• Prevents overgrowing of pipe walls with paraffin and sulfur deposits.

In light industry:

• Increases wear resistance of PTFE products and coatings based on it • Increases physical and mechanical characteristics of rubber products, and paints and varnishes.

Quasicrystals is a new class of materials, discovered in 1984, with unique properties. Currently, a lot of research is being carried out in the world in the field of application of quasicrystals in almost all areas of industry. An obstacle to the large-scale practical application of quasicrystals is the high cost of synthesizing this material. NANOKOM has developed a unique technology that has reduced the cost of production to a level that provides the possibility of its application on an industrial scale.

Specifications:

Density: 4 g / cm3

Dispersion of the base powder: 1-10 µm

Steel Friction Coefficient: 0.14

Hardness: 800-1000 HV

Thermal conductivity: 2 W / (m ∙ K)

Resistivity (at T room): 4.5 mOhm ∙ cm

Modifier assignment

1. Improving the mechanical characteristics and adhesion to metals of polymers, elastomers and materials based on them;

2. Decrease in friction, increase in energy efficiency and resource of friction units and mechanisms in normal working conditions, as well as in conditions of “oil starvation” and “dry friction”;

3. Increases wear resistance and abrasion in polytetrafluoroethylene (Teflon, PTFE, Fluoroplast-4) by 2 to 3 orders of magnitude;

4. Improving the physico-mechanical properties of babbits and increasing the life of products from babbits based on quasicrystals;

5. Reinforcing metals to create anti-friction composite materials;

6. Formation of coatings on metals to reduce the coefficient of friction, as well as on glass to increase the level of hydrophobicity.

Modifier Application

In mechanical engineering, metallurgy and energy:

• Reduces friction losses and energy consumption, lowers temperature and noise of working mechanisms, increases the life of the mechanisms, prevents grasping and jamming of nodes and parts;

• Increases the service life of bearings, gears, transmissions when added to oil and grease;

• Increases the strength of polymer composite materials, plastic products.

In oilfield services:

• Extends the life of rubber products, prevents peeling of rubber from metal;

• Increases the service life of rubbing units, reduces the coefficient of friction at the contact point in metal-metal and metal-rock pairs;

• Prevents overgrowing of pipe walls with paraffin and sulfur deposits.

In light industry:

• Increases wear resistance of PTFE products and coatings based on it • Increases physical and mechanical characteristics of rubber products, and paints and varnishes.

Specification

1. Модификатор_для__РТИ_(РУС).pdf2. Модификатор_для_полимеров_(РУС).pdf

3. MSDS_(RUS).pdf

4. Модификатор_(РУС).pdf

5. ТУ_24_45_30-005-31800065-2018_МОДИФИКАТОР_ПОРОШКОВЫЙ_КВАЗИКРИСТАЛЛИЧЕСКИЙ_(РУС).pdf

6. Презентация_модификатора_КК_(RUS).pdf

7. A_modifier_powder_quasicrystalline_(ENG).pdf

8. TC_24_45_30-005-31800065-2018_POWEDER_MODIFIER_QUASICRYSTALLINE_(ENG).pdf

9. MSDS_(ENG).pdf

10. Presentation_quasicrystalls_Al-Cu-Fe_(ENG).pdf