Description

Our specialists will thoroughly study all the characteristics of your product and production features, and offer a Big Bag filling station (BBS) that meets all the initial data. We are different in that we offer turnkey project implementation. This means that we take on all stages of the project, from design to installation, commissioning and personnel training. You receive Big Bag filling equipment (BBS) that will fully meet your expectations and requirements.

Your production is our priority! Individual Big Bag filling stations from MelService

Each client is unique, and we know how important it is to select equipment that will ideally fit into your production line. MelService specialists develop Big Bag dispensers (BBS), taking into account all the nuances of your business.

What we offer:

1. Individual approach: We carefully analyze the characteristics of your product and production conditions to offer a filling station that exactly meets your needs.

2. Turnkey project: From concept development to installation and commissioning – we take on the entire cycle of work. All you have to do is enjoy the result.

3. Personnel training: We will train your staff so that each employee can confidently operate the new equipment.

4. Reliability and durability: All our filling stations undergo thorough testing before delivery, guaranteeing their flawless operation for many years.

Why choose us:- More than 20 years of experience in creating specialized solutions for the food, chemical and agricultural industries.

- Modern technologies and high-quality materials that ensure high precision and reliability of the equipment.

- Ongoing customer support at all stages of cooperation.

Reach new heights with MelService! Order an individual Big Bag filling station (MKR) and see that your production will become even more efficient and productive. We will help you optimize processes and take your business to a new level!

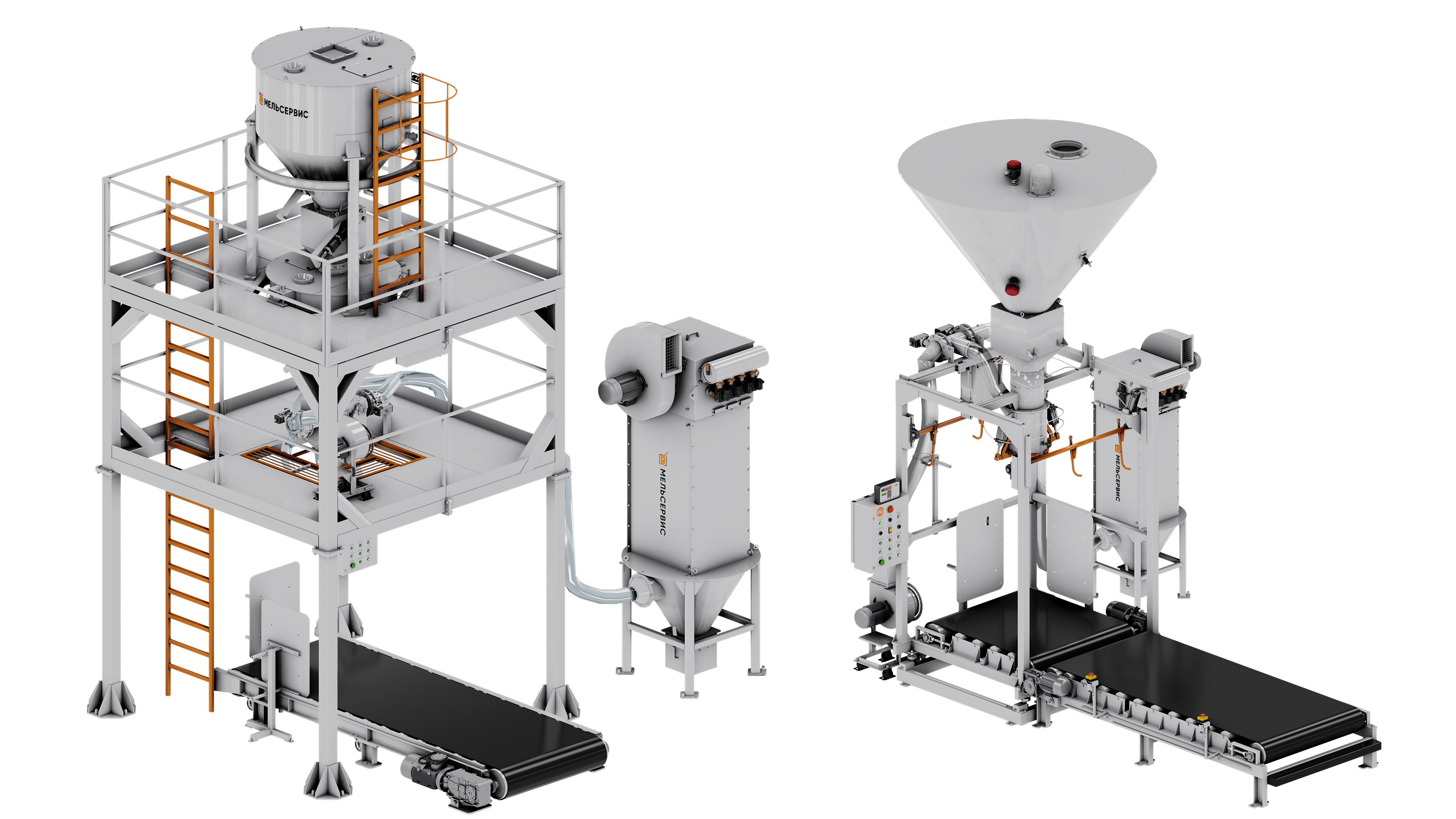

Based on the Big Bag dispenser - MVD-MS-500/1000 ("net")

Maximum productivity

Weighing is carried out in a weigh hopper

Two types of weigh batchers are used - 500 kg / 1000 kg

Equipment with overhead and suspended hoppers

Semi-automatic packaging

Your production is our priority! Individual Big Bag filling stations from MelService

Each client is unique, and we know how important it is to select equipment that will ideally fit into your production line. MelService specialists develop Big Bag dispensers (BBS), taking into account all the nuances of your business.

What we offer:

1. Individual approach: We carefully analyze the characteristics of your product and production conditions to offer a filling station that exactly meets your needs.

2. Turnkey project: From concept development to installation and commissioning – we take on the entire cycle of work. All you have to do is enjoy the result.

3. Personnel training: We will train your staff so that each employee can confidently operate the new equipment.

4. Reliability and durability: All our filling stations undergo thorough testing before delivery, guaranteeing their flawless operation for many years.

Why choose us:- More than 20 years of experience in creating specialized solutions for the food, chemical and agricultural industries.

- Modern technologies and high-quality materials that ensure high precision and reliability of the equipment.

- Ongoing customer support at all stages of cooperation.

Reach new heights with MelService! Order an individual Big Bag filling station (MKR) and see that your production will become even more efficient and productive. We will help you optimize processes and take your business to a new level!

Based on the Big Bag dispenser - MVD-MS-500/1000 ("net")

Maximum productivity

Weighing is carried out in a weigh hopper

Two types of weigh batchers are used - 500 kg / 1000 kg

Equipment with overhead and suspended hoppers

Semi-automatic packaging