Description

What does it do?

Zyfra Heat Treatment AI assists with and improves planning, technical optimization, real-time operations and analytics. The focus is pipe production for lines with a capacity of 30 000 tons a year and more.

Scheduling

Advanced Planning and Scheduling functionality,

focusing on improving the production margin

Optimization

Providing the best approach for heat treating pipes

and includes online corrections

Features

Advanced Scheduling

New grades fast start

On-demand, Instant Rescheduling

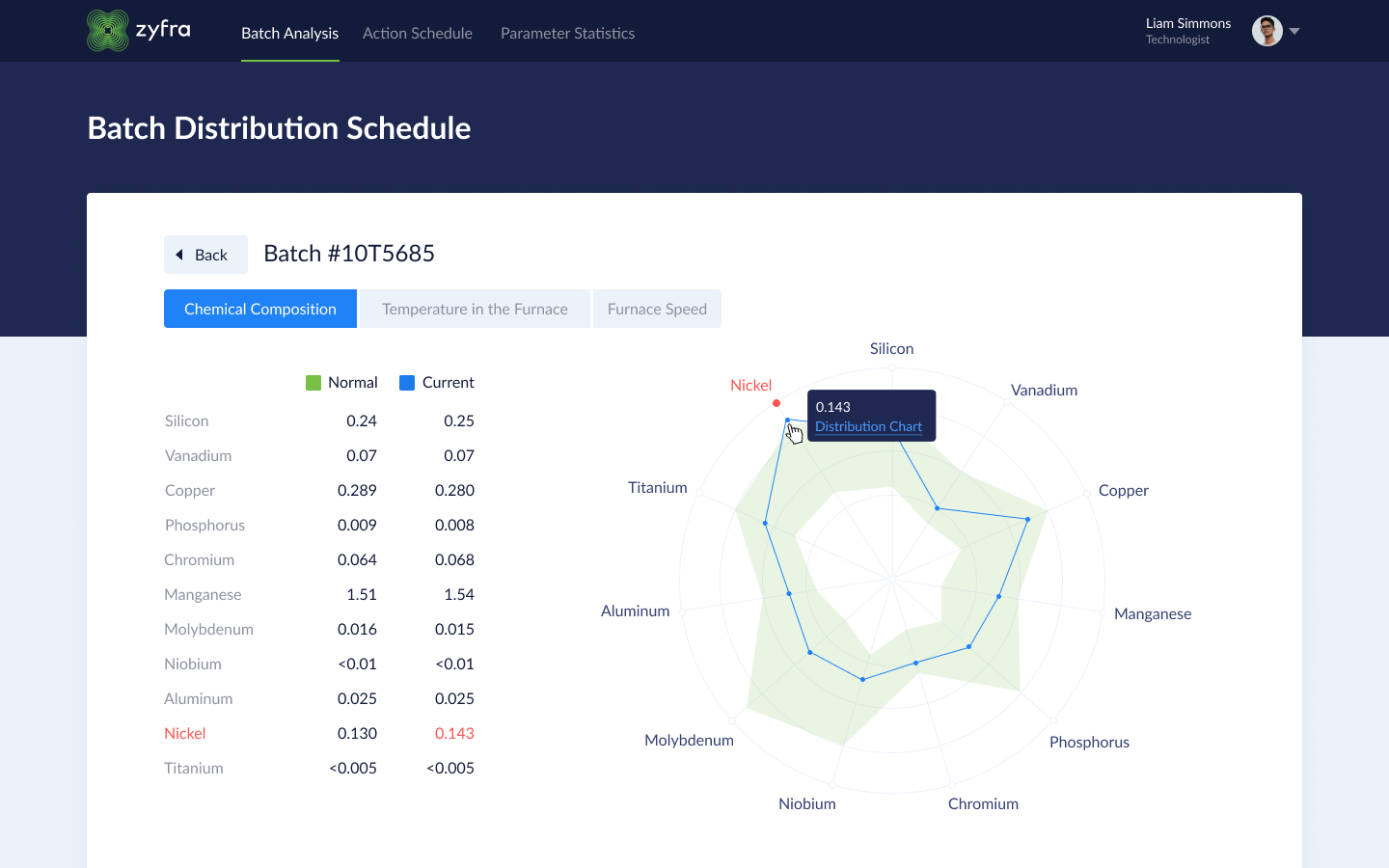

Quality inspection

Furnace and Cooling auto-setup

Efficiency Reports

Real-time furnace control

An in-depth look at the Features

ADVANCED PLANNING

& SCHEDULING

This module provides optimal shift planning, taking into account all current, logged orders, their dates, priority and margin — transition times, supply limitations and delivery logistic limitations.

INSTANT

RE-SCHEDULING

This provides fully automatic scheduling, data integration, less than 1-minute ‘new plan’ gene- ration and the best new schedule while limiting the number of changes to a minimum.

REAL-TIME DECISION

SUPPORT SYSTEM

This system monitors temperatures in the furnaces and sprayer/tub. It can apply suggested furnace section temperature changes and ensure that all pipes in the batch maintain quality despite changes in the furnace state. This means overall quality is improved, both in random tests and in actual product to client.

TECHNOLOGY INTELLIGENCE

We had equipment fluctuations, how did this affect production? We used new AI-suggested modes, how did it help? A batch failed quality control, how is it different from other batches? We produced 1000 tons more, but what is our margin?

Zyfra Heat Treatment AI assists with and improves planning, technical optimization, real-time operations and analytics. The focus is pipe production for lines with a capacity of 30 000 tons a year and more.

Scheduling

Advanced Planning and Scheduling functionality,

focusing on improving the production margin

Optimization

Providing the best approach for heat treating pipes

and includes online corrections

Features

Advanced Scheduling

New grades fast start

On-demand, Instant Rescheduling

Quality inspection

Furnace and Cooling auto-setup

Efficiency Reports

Real-time furnace control

An in-depth look at the Features

ADVANCED PLANNING

& SCHEDULING

This module provides optimal shift planning, taking into account all current, logged orders, their dates, priority and margin — transition times, supply limitations and delivery logistic limitations.

INSTANT

RE-SCHEDULING

This provides fully automatic scheduling, data integration, less than 1-minute ‘new plan’ gene- ration and the best new schedule while limiting the number of changes to a minimum.

REAL-TIME DECISION

SUPPORT SYSTEM

This system monitors temperatures in the furnaces and sprayer/tub. It can apply suggested furnace section temperature changes and ensure that all pipes in the batch maintain quality despite changes in the furnace state. This means overall quality is improved, both in random tests and in actual product to client.

TECHNOLOGY INTELLIGENCE

We had equipment fluctuations, how did this affect production? We used new AI-suggested modes, how did it help? A batch failed quality control, how is it different from other batches? We produced 1000 tons more, but what is our margin?