|

Zyfra Industrial IoT Platform

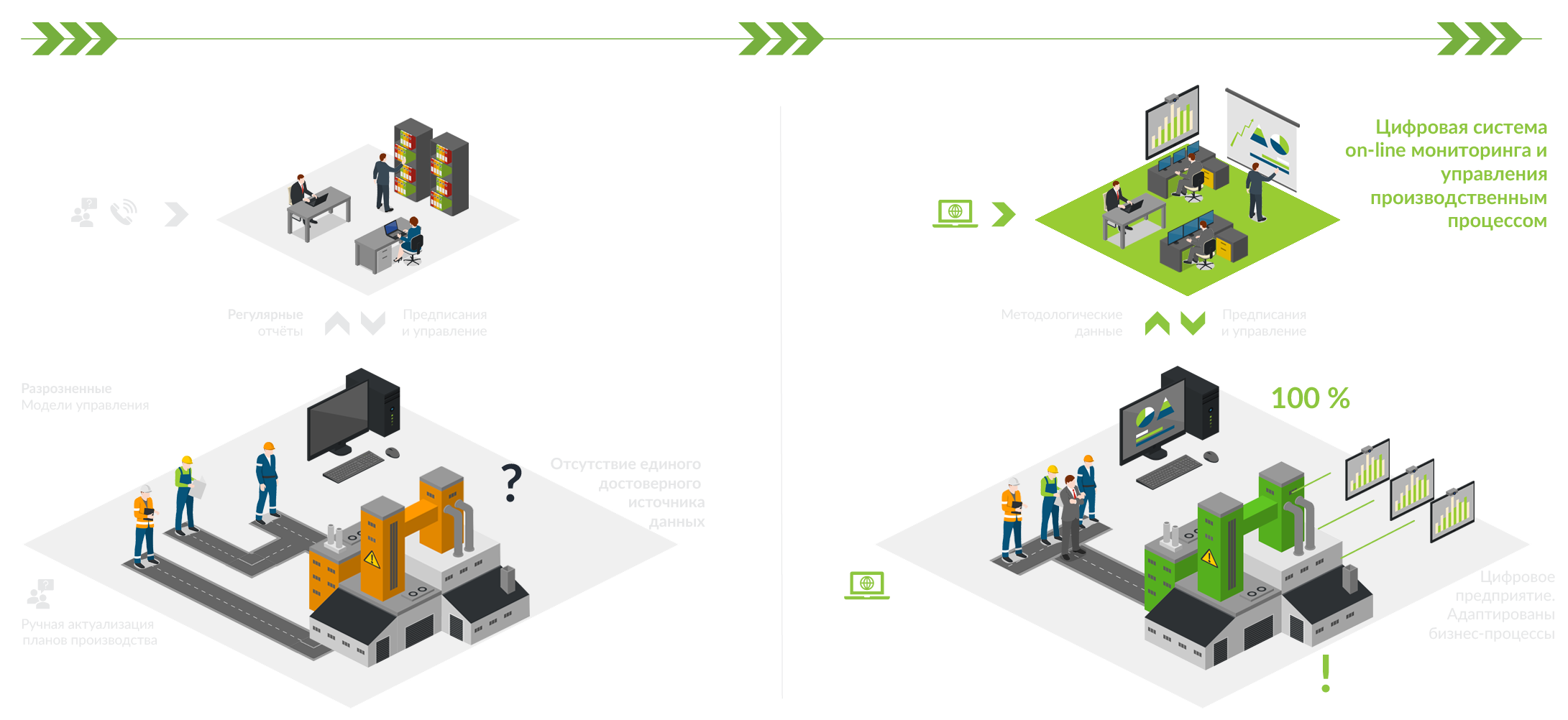

First step in preparing an enterprise for going

digital and for the use of artificial intelligence

Part number:

Supplier:

Zyfra Description

A tool built to combine the digital elements of the industrial production process as well as business processes. It provides

the possibility for basic automation of technology based processes in support of uninterrupted, continuous production, the creation of applied applications and data preparation for machine learning and artificial intelligence.

Creating a single digital layer within the production

Creating digital copies and predictive models using AI

Combining dissimilar information and automated systems into units

The collection, storage and analysis of both production and technical data

Monitoring the technical process as well as notifications of personnel events

Who is Zyfra IIoT Platform for?

IT integrators

Dispatchers

Technical plant operators

Heads of Production Units

Technical engineers

IT departments

It allows for the combination of various, different technologies and tools in order to create solutions that meet modern business requirements, in a short time and at minimal cost.

Cases

TECHNOLOGICAL PROCESS STABILIZATION

Product used:

Zyfra Industrial IoT Platform

Goal

To reduce consumption of useful component, while maintaining quality.

Effects

Reducing useful component consumption

Reducing production costs by 3-6%

Zyfra IIoT Platform function

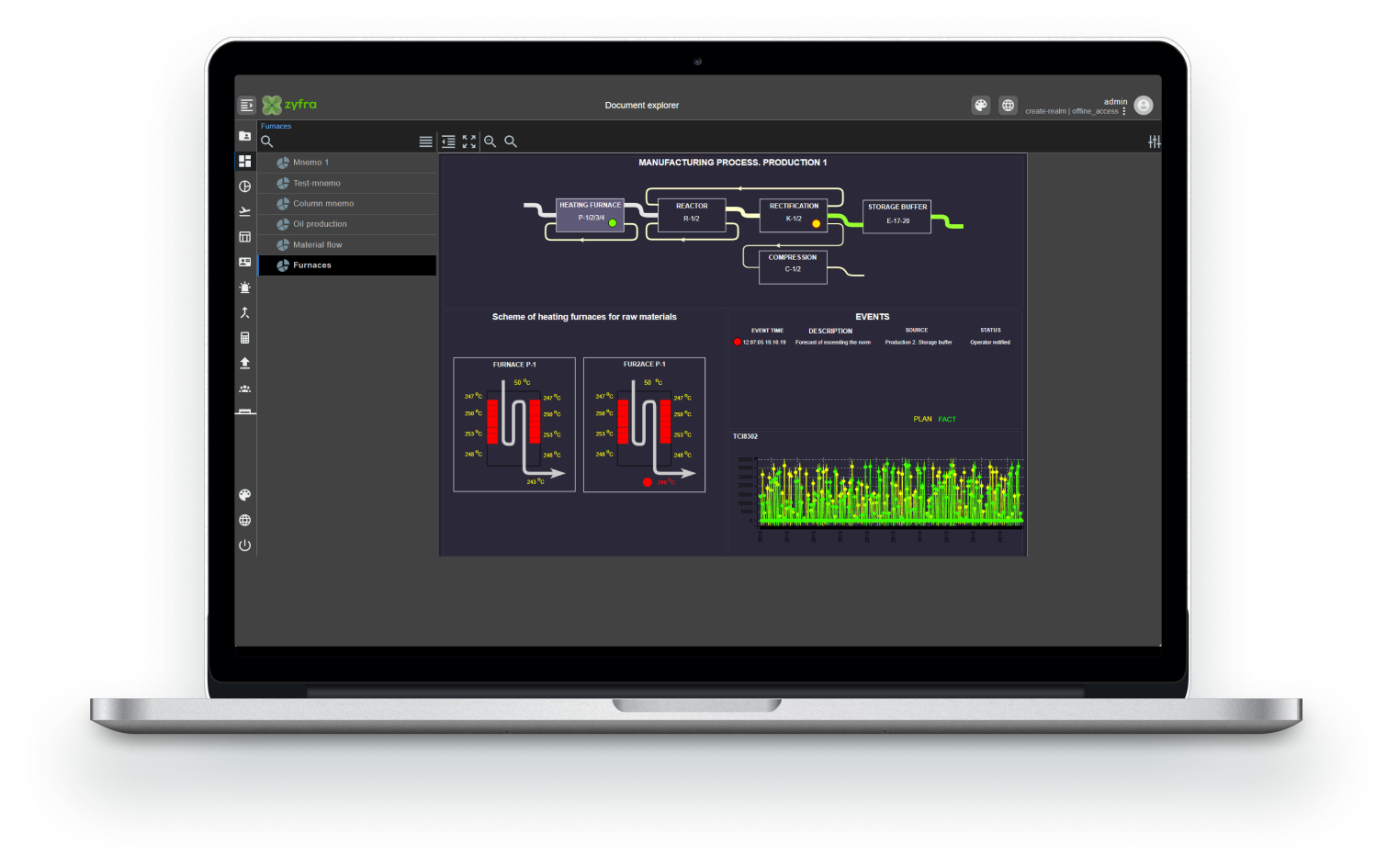

Collecting data, monitoring violations, presenting a visualization of the production process for dispatcher control and managing the process in an optimal mode (6-sigma principle).

Technological process stabilization

THE CALCULATION OF THE TECHNOLOGICAL

COST FOR A BATCH OF PRODUCT

Product used:

Zyfra Industrial IoT Platform

Goal

To solve the problem of cost analysis.

Effects

A cost reduction of 4-6%

Zyfra IIoT Platform function

Collecting and archiving data at all stages

of production. Integrating with systems

of a lower (process control system)

and upper (ERP) level. Providing data

to the calculation module (a model

of our own design). The visualization

and gradation of cost sources.

Creating a single digital layer within the production

Creating digital copies and predictive models using AI

Combining dissimilar information and automated systems into units

The collection, storage and analysis of both production and technical data

Monitoring the technical process as well as notifications of personnel events

Who is Zyfra IIoT Platform for?

IT integrators

Dispatchers

Technical plant operators

Heads of Production Units

Technical engineers

IT departments

It allows for the combination of various, different technologies and tools in order to create solutions that meet modern business requirements, in a short time and at minimal cost.

Cases

TECHNOLOGICAL PROCESS STABILIZATION

Product used:

Zyfra Industrial IoT Platform

Goal

To reduce consumption of useful component, while maintaining quality.

Effects

Reducing useful component consumption

Reducing production costs by 3-6%

Zyfra IIoT Platform function

Collecting data, monitoring violations, presenting a visualization of the production process for dispatcher control and managing the process in an optimal mode (6-sigma principle).

Technological process stabilization

THE CALCULATION OF THE TECHNOLOGICAL

COST FOR A BATCH OF PRODUCT

Product used:

Zyfra Industrial IoT Platform

Goal

To solve the problem of cost analysis.

Effects

A cost reduction of 4-6%

Zyfra IIoT Platform function

Collecting and archiving data at all stages

of production. Integrating with systems

of a lower (process control system)

and upper (ERP) level. Providing data

to the calculation module (a model

of our own design). The visualization

and gradation of cost sources.