|

Railcar identification and inspection, rail scales automation

Railcar identification and inspection, rail scales automation

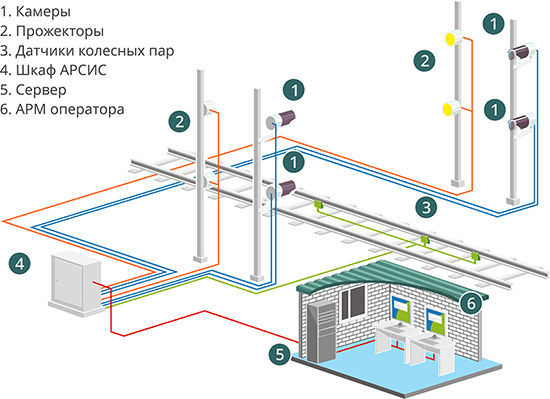

ARSCIS is a family of solutions that utilize railcar number recognition technology to identify separate railcars, manage product shipping by rail, monitor railcar movement and location, etc. for metrology, logistics, and security purposes.

Part number:

Supplier:

Mallenom SystemsDescription

For commodity production and metrology services

Reduction of human factor influence on shipment process

Documenting of each railcar weighting

Reduction of labour consumption and increased speed of shipment

Automation of workflow

Absence of staff on railway lines

For security services

Tracking of railcar location

Identification of “suspicious” movements and delays of railcars

Detection of changes in car weight

Inspection of railcars using thermal vision and laser scanning facilities

For logistics departments and railway shops

Inspection of railcars without staff on railway lines

Generation of photo and video materials for complaint management

Check of railcar displacement and movement

Automatic monitoring of time a railcar spends in the premises

Check of the geometry of cargos and railcars

ARSCIS performs the following functions:

Calculation of number of railcars

Generation of image of every railcar

Automatic identification of railcar numbers from sides and frame

Generation of information on railcars: photo, video, inventory number, speed of passage, date/time, number of axles, type of railcar, etc.

Identification of locomotives and their exclusion from reports

Acquisition and aggregation of information from scales and other systems

Archiving of all information on passing trains

Report generation

Data transfer to external information systems

Specialized options

Recognition in the conditions of railcar reverse motion

Identification of ISO container numbers

Explosion-proof version of trackside equipment

Upper surveillance video camera for monitoring of railcar loading

Automatic control of railcar weight changes at return passage (for rail scales)

Monitoring of time the railcar spends in the premises, indication of the violation of time allowed

Inspection of railcar dimensions

Automatic report generation and saving in the enterprise network folder

Thermal-imaging shooting

Inspection of railcar dimensions

Integration with rail scales

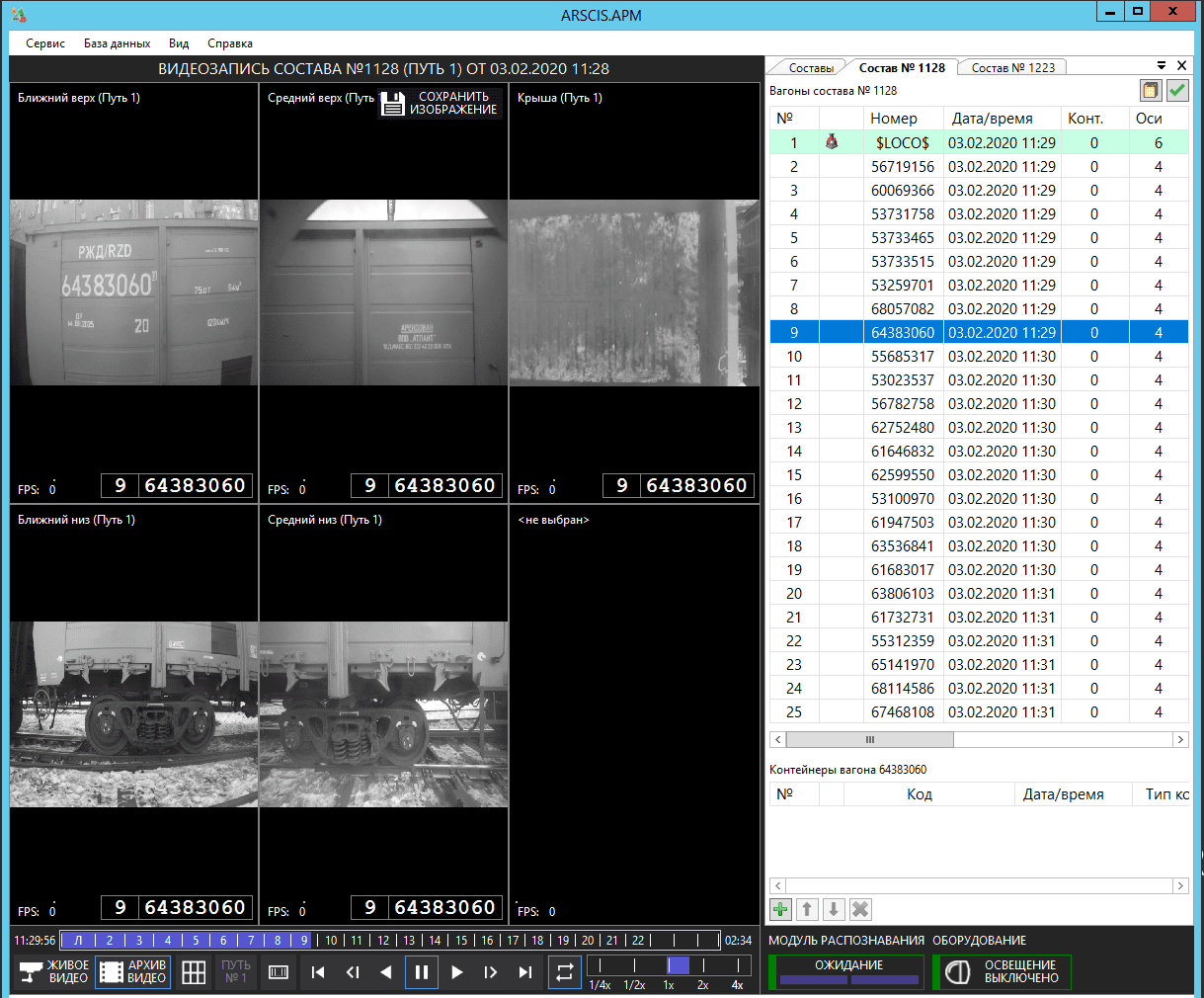

Automated workstation (AWS)

Depending on the task solved, ARSCIS system can be completed with an AWS of security and commercial inspection specialist or AWS of railcar scales operator.

Key functions:

Comparison of identified number of each railcar and video record of its passage from several cameras

Display of video from several cameras in the video wall format with possibility of flexible adjustment

Access to video archive, display of historical information

Enhanced set of functions for operation with railcar video archive (display of video at different rates, synchronous display of video from different cameras, still frame expansion, etc.)

Speed enforcement

Monitoring of serviceability of system hardware and software

Sound indication at the start of train passage

Assignment of access privileges (administrator, operator, supervisor)

Generation and printing of reports

Option – display of video of railcar bottom

Option – display of video from thermal vision camera

Option – automatic monitoring of time a railcar spends in the premises, indication of blacklisted railscar passage, comparison with supplementary sheet, etc.

Key functions:

Comparison of identified railcar number, weight received from the railcar scales and video record of its passage from several cameras

Access to video archive, display of historical information

Monitoring of serviceability of system hardware and software

Sound indication of start of train passage

Automatic calculation of net weight

Speed enforcement during movement over scales

Monitoring of serviceability of identification module, wheelset sensors, and cameras

Assignment of access privileges (administrator, operator, supervisor)

Generation and printing of reports

Reduction of human factor influence on shipment process

Documenting of each railcar weighting

Reduction of labour consumption and increased speed of shipment

Automation of workflow

Absence of staff on railway lines

For security services

Tracking of railcar location

Identification of “suspicious” movements and delays of railcars

Detection of changes in car weight

Inspection of railcars using thermal vision and laser scanning facilities

For logistics departments and railway shops

Inspection of railcars without staff on railway lines

Generation of photo and video materials for complaint management

Check of railcar displacement and movement

Automatic monitoring of time a railcar spends in the premises

Check of the geometry of cargos and railcars

ARSCIS performs the following functions:

Calculation of number of railcars

Generation of image of every railcar

Automatic identification of railcar numbers from sides and frame

Generation of information on railcars: photo, video, inventory number, speed of passage, date/time, number of axles, type of railcar, etc.

Identification of locomotives and their exclusion from reports

Acquisition and aggregation of information from scales and other systems

Archiving of all information on passing trains

Report generation

Data transfer to external information systems

Specialized options

Recognition in the conditions of railcar reverse motion

Identification of ISO container numbers

Explosion-proof version of trackside equipment

Upper surveillance video camera for monitoring of railcar loading

Automatic control of railcar weight changes at return passage (for rail scales)

Monitoring of time the railcar spends in the premises, indication of the violation of time allowed

Inspection of railcar dimensions

Automatic report generation and saving in the enterprise network folder

Thermal-imaging shooting

Inspection of railcar dimensions

Integration with rail scales

Automated workstation (AWS)

Depending on the task solved, ARSCIS system can be completed with an AWS of security and commercial inspection specialist or AWS of railcar scales operator.

Key functions:

Comparison of identified number of each railcar and video record of its passage from several cameras

Display of video from several cameras in the video wall format with possibility of flexible adjustment

Access to video archive, display of historical information

Enhanced set of functions for operation with railcar video archive (display of video at different rates, synchronous display of video from different cameras, still frame expansion, etc.)

Speed enforcement

Monitoring of serviceability of system hardware and software

Sound indication at the start of train passage

Assignment of access privileges (administrator, operator, supervisor)

Generation and printing of reports

Option – display of video of railcar bottom

Option – display of video from thermal vision camera

Option – automatic monitoring of time a railcar spends in the premises, indication of blacklisted railscar passage, comparison with supplementary sheet, etc.

Key functions:

Comparison of identified railcar number, weight received from the railcar scales and video record of its passage from several cameras

Access to video archive, display of historical information

Monitoring of serviceability of system hardware and software

Sound indication of start of train passage

Automatic calculation of net weight

Speed enforcement during movement over scales

Monitoring of serviceability of identification module, wheelset sensors, and cameras

Assignment of access privileges (administrator, operator, supervisor)

Generation and printing of reports