|

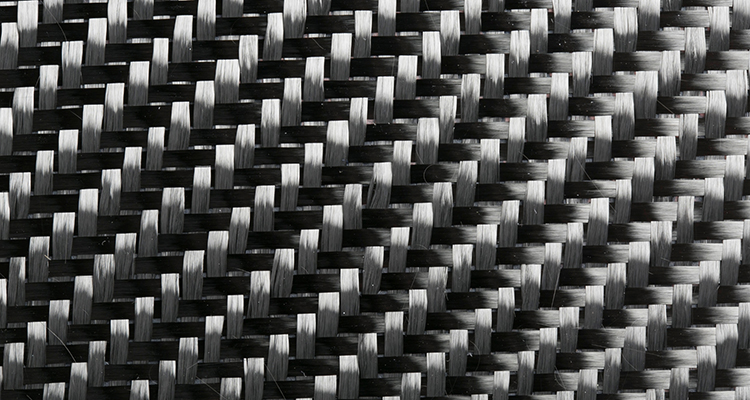

Fabric with binder

Carbon fiber fabric is used as a reinforcing filler in the production of composite materials

Part number:

Supplier:

LLC "ITEKMA"Description

Carbon fiber fabric is used as a reinforcing filler in the production of composite materials. Carbon fiber has a strength-weight ratio of 8-17 times and the modulus of elasticity is 5-13 times higher than that of steel, aluminum and titanium. The coefficient of thermal expansion of carbon fiber is 15-20 times lower than that of steel and aluminum. The high thermal stability of carbon fibers allows them to be used as thermal insulation and thermal screens up to 2000 °C in an inert atmosphere, up to 450 °C in the air. Carbon fiber has good corrosion resistance to gas and liquid media in comparison with steel.

When choosing a carbon fiber fabric, you need to consider the following characteristics:

Fiber brand: the mechanical characteristics of the fabric depend on it, such as tensile strength and modulus;

Drapability: it is important in the manufacture of parts with a complex profile;

Mechanical characteristics: it is important to take into account the fiber brand, as well as the direction and degree of load on the part;

Stability of the fabric: it determines the uniformity of mechanical properties throughout the area and the convenience of working with the fabric.

When choosing a carbon fiber fabric, you need to consider the following characteristics:

Fiber brand: the mechanical characteristics of the fabric depend on it, such as tensile strength and modulus;

Drapability: it is important in the manufacture of parts with a complex profile;

Mechanical characteristics: it is important to take into account the fiber brand, as well as the direction and degree of load on the part;

Stability of the fabric: it determines the uniformity of mechanical properties throughout the area and the convenience of working with the fabric.