|

Extraction of Anhydrous Oil Technology Development and Use

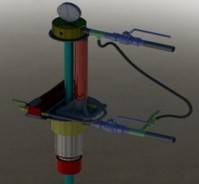

The main technology is the extraction of anhydrous oil using by a compressor method using a depth switch valve.

Part number:

Supplier:

LLC "NANOCOM"Description

The main technology is the extraction of anhydrous oil using by a compressor method using a depth switch valve. A prototype of the deep switch valve is made and preliminary tested.

The technology has been patented.

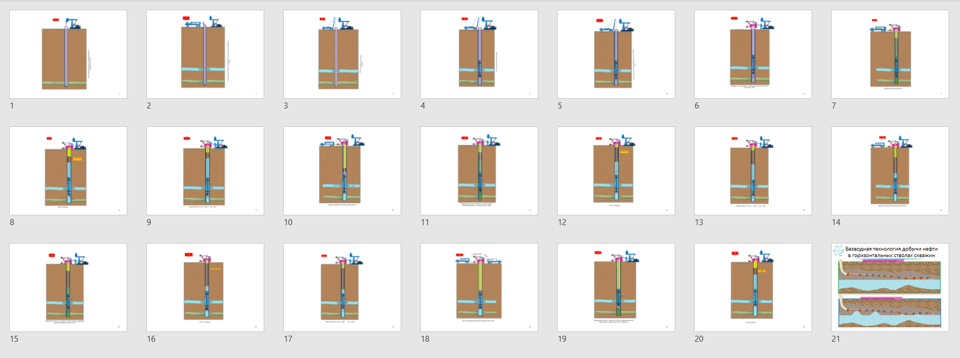

The second proposed technology is the production of anhydrous oil in horizontal boreholes using oil and water flow selectors. There is a unique design of automatic inflow control (AUCP) either of horizontal boreholes of new wells or of horizontal boreholes with cutting of side boreholes. The technology is patented. We are looking for financial resources to start production of equipment.

It is known that the resources of "easily accessible" oil have been exhausted. However, in companies, the emphasis is still on intensification. There are huge investments into the output and development of new hard-to-reach fields, shale reserves and technologies (bazhen, hydraulic fracturing, complex horizontal and multi-barrel wells, etc.), which are extremely expensive, or give a short-term effect. And yet there are no ways to reduce expenses.

But the deciding of the problem of waterlogging is quite slowly.

Downhole separation is the only correct direction in energy saving and, consequently, increasing the economic efficiency of oil production. It is especially in the conditions of overproduction of oil in the world, and of extremely low prices.

But we immediately decided that downhole separation is not compatible with using of pumping, and therefore new downhole and wellhead equipment is developed for the technology of producing anhydrous oil using a compressor.

We make you an offer to participate in the promotion of a new technology for oil production with a multi-billion-dollar perspective. Pilot testing should take 6-7 months, including preparatory work. The required minimum amount of funding is 60 million rubles.

Patents have been issued for brand-new equipment.

The main goal of the innovation is to introduce technologies that reduce the cost of production of each ton of oil by saving energy and reducing capital expenditures on field infrastructure and equipment.

The technology will use 4 types of new downhole equipment:

1. wellhead Equipment.

2. Self-contained anchor for mounting the removable shank in the service column;

3. mounting Assembly of the removable shank in the well;

4. the device for fixing the shank to remove it.

Oil well debit per day: up to 160 m^3 per day;

Volume of associated reservoir water per day: 0 l;

Equipment cost: 1.5 million rubles.

Repair capacity: Low

At the present stage, the oil and gas complex is goaled at a vector of development with savings in production costs.

The developed technology can almost completely replace the field equipment at all 160 thousand wells, including where the "flow rate is small".

Current stages:

• A prototype of the equipment was created and prototype testing was carried out at the Tyazhpressmash plant in Ryazan, Russia

• Developed documentation and drawings for manufacturing of industrial complete sets of equipment in three basic sizes.

• Developed a test program and cost estimates for field testing of equipment and testing of anhydrous oil production technology without the use of underground pumps

• 16.01.2020 received a decision to grant a patent for the application for invention No. 2019109676 dated 02.04.2019

The technology has been patented.

The second proposed technology is the production of anhydrous oil in horizontal boreholes using oil and water flow selectors. There is a unique design of automatic inflow control (AUCP) either of horizontal boreholes of new wells or of horizontal boreholes with cutting of side boreholes. The technology is patented. We are looking for financial resources to start production of equipment.

It is known that the resources of "easily accessible" oil have been exhausted. However, in companies, the emphasis is still on intensification. There are huge investments into the output and development of new hard-to-reach fields, shale reserves and technologies (bazhen, hydraulic fracturing, complex horizontal and multi-barrel wells, etc.), which are extremely expensive, or give a short-term effect. And yet there are no ways to reduce expenses.

But the deciding of the problem of waterlogging is quite slowly.

Downhole separation is the only correct direction in energy saving and, consequently, increasing the economic efficiency of oil production. It is especially in the conditions of overproduction of oil in the world, and of extremely low prices.

But we immediately decided that downhole separation is not compatible with using of pumping, and therefore new downhole and wellhead equipment is developed for the technology of producing anhydrous oil using a compressor.

We make you an offer to participate in the promotion of a new technology for oil production with a multi-billion-dollar perspective. Pilot testing should take 6-7 months, including preparatory work. The required minimum amount of funding is 60 million rubles.

Patents have been issued for brand-new equipment.

The main goal of the innovation is to introduce technologies that reduce the cost of production of each ton of oil by saving energy and reducing capital expenditures on field infrastructure and equipment.

The technology will use 4 types of new downhole equipment:

1. wellhead Equipment.

2. Self-contained anchor for mounting the removable shank in the service column;

3. mounting Assembly of the removable shank in the well;

4. the device for fixing the shank to remove it.

Oil well debit per day: up to 160 m^3 per day;

Volume of associated reservoir water per day: 0 l;

Equipment cost: 1.5 million rubles.

Repair capacity: Low

At the present stage, the oil and gas complex is goaled at a vector of development with savings in production costs.

The developed technology can almost completely replace the field equipment at all 160 thousand wells, including where the "flow rate is small".

Current stages:

• A prototype of the equipment was created and prototype testing was carried out at the Tyazhpressmash plant in Ryazan, Russia

• Developed documentation and drawings for manufacturing of industrial complete sets of equipment in three basic sizes.

• Developed a test program and cost estimates for field testing of equipment and testing of anhydrous oil production technology without the use of underground pumps

• 16.01.2020 received a decision to grant a patent for the application for invention No. 2019109676 dated 02.04.2019