Description

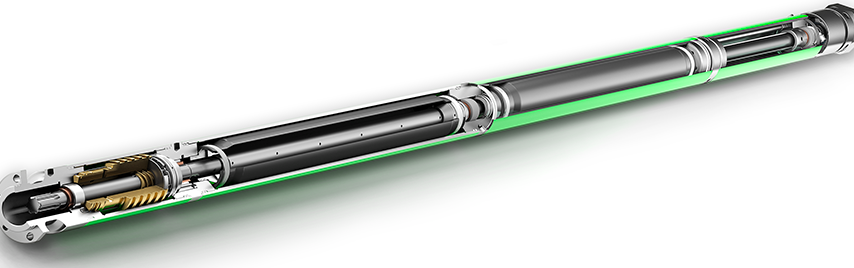

Modular design allows to perform fast repair and modernization of the protector depends on the operating conditions. Unified parts and consumables, such as shafts, housings and nipples, are used in the production.

Assembly scheme shows number of protection levels (successive module connection) and compensative properties of protectors (that are doubled in case of parallel connection of bladder modules).

• Successive module connection is the redundancy of the module below and implies the presence of the face seal between them (in case of failure of one of the modules, the following module provides the motor protection);

• Parallel connection increase the volume of compensating oil, which will be equal to the total amount of module objects (parallel connection is available only for bladder modules).

Bladder intended to separate fluid and AM oil and compensating temperature changes caused by the work of the AM. Tubular labyrinth lock the fluid, preventing its penetration into the bladder module.

Axial bearing design provides the rotation of the shaft in both directions and promotes the effective heat exchange between the runner and the external space (rising fluid). Thrust bearings are able to take the significant loads, transmitted from the pump’s shaft, which has no axial bearing.

Assembly scheme shows number of protection levels (successive module connection) and compensative properties of protectors (that are doubled in case of parallel connection of bladder modules).

• Successive module connection is the redundancy of the module below and implies the presence of the face seal between them (in case of failure of one of the modules, the following module provides the motor protection);

• Parallel connection increase the volume of compensating oil, which will be equal to the total amount of module objects (parallel connection is available only for bladder modules).

Bladder intended to separate fluid and AM oil and compensating temperature changes caused by the work of the AM. Tubular labyrinth lock the fluid, preventing its penetration into the bladder module.

Axial bearing design provides the rotation of the shaft in both directions and promotes the effective heat exchange between the runner and the external space (rising fluid). Thrust bearings are able to take the significant loads, transmitted from the pump’s shaft, which has no axial bearing.