|

Submersible motors (asynchronous)

Asynchronous motors (AM) are used as a drive for ESP units

Part number:

Description

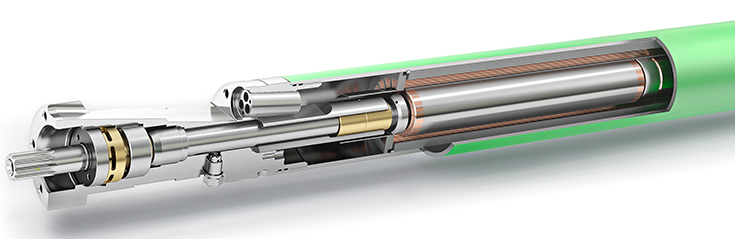

Asynchronous motors (AM) are used as a drive for ESP: they are produced in 3 series:

406, 449 and 512 with the power varies from 16 to 450 kW. A wide range of produced AM

of various capacities allows to select the most optimal combination of “engine - pump”

system to ensure the unit operation with the maximum efficiency. Manufacturing technique provides high quality and reliability of AM production. The stator is made with a

closed slot, which excludes the possibility of the internal cavity pollution, which allows to

successfully apply tubular slotted insulation.

In the AM rotor we applied original bearings with mechanical fixation from the rotation

which provides the possibility of easy axial movement along the shaft.

The use of special materials makes it possible to exploit AM at reservoir temperature

up to 150 °C (up to 170 ° С in high-temperature resistant design).

After assembly on special stands, where we control the quality of individual components, the AM is tested in conditions which are close to real ones, including heating up

to operating temperatures. 100% of the engines are subjected to the tests, and after it,

they are all sorted out and carefully checked. The insulation resistance is monitored on

the polarization index.

Electric motors can operates with the telemetry systems of various manufacturers.

406, 449 and 512 with the power varies from 16 to 450 kW. A wide range of produced AM

of various capacities allows to select the most optimal combination of “engine - pump”

system to ensure the unit operation with the maximum efficiency. Manufacturing technique provides high quality and reliability of AM production. The stator is made with a

closed slot, which excludes the possibility of the internal cavity pollution, which allows to

successfully apply tubular slotted insulation.

In the AM rotor we applied original bearings with mechanical fixation from the rotation

which provides the possibility of easy axial movement along the shaft.

The use of special materials makes it possible to exploit AM at reservoir temperature

up to 150 °C (up to 170 ° С in high-temperature resistant design).

After assembly on special stands, where we control the quality of individual components, the AM is tested in conditions which are close to real ones, including heating up

to operating temperatures. 100% of the engines are subjected to the tests, and after it,

they are all sorted out and carefully checked. The insulation resistance is monitored on

the polarization index.

Electric motors can operates with the telemetry systems of various manufacturers.