|

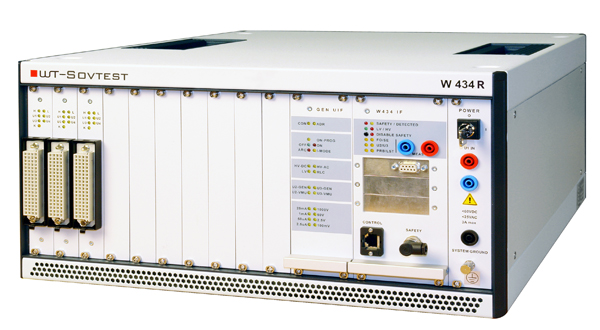

Wire Mount Tester W434R

Wire harness tester WeeTech W434 is developed for detection and localization of wire harness, binders and cables defects and for components’ functional control. High-speed measure instrument allows automatic inspection of tested products for suitability to connections table; it also allows to measure connection quality and to check quality of isolation and components.

Part number:

Supplier:

Sovtest ATE LLCDescription

Area of its application is various, starting with tests for simple binders’ breakdown and finishing with complex analysis of the whole scheme in devices.

Module architecture of W434 series testers allows choosing an appropriate configuration for any requirements for testing of products.

W 434 testers’ features:

High rates of speed, measure accuracy and reliability.

Easy maintenance. It is possible to add operator’s instructions.

Number of testing channels varies from 64 to 6656 (more than 50 000 in W454 configuration).

Integrity and separateness control for documentation or reference mark suitability.

Possibility of different connectors mounting on the tester front panel.

Examples of different connectors’ usage on the tester output:

High-voltage resistance measurements and tests of isolation electric strength.

Usage of mass testing algorithm for testing speed increase.

Possibility of components functional tests.

Intuitive programming mode does not require qualification.

Automatic generation of product connection scheme according to documentation or reference mark.

Option of big items distributed testing.

Option of plugged-in adaptor automatic detection.

Quality connection measurements (overall resistance measurement, phase angle measurement, power dispersion measurement and others).

Twisted-pair wire and coaxial cables testing. Detection of double transposition (changing of wires mutual disposition) and incorrect core screening.

Module architecture of W434 series testers allows choosing an appropriate configuration for any requirements for testing of products.

W 434 testers’ features:

High rates of speed, measure accuracy and reliability.

Easy maintenance. It is possible to add operator’s instructions.

Number of testing channels varies from 64 to 6656 (more than 50 000 in W454 configuration).

Integrity and separateness control for documentation or reference mark suitability.

Possibility of different connectors mounting on the tester front panel.

Examples of different connectors’ usage on the tester output:

High-voltage resistance measurements and tests of isolation electric strength.

Usage of mass testing algorithm for testing speed increase.

Possibility of components functional tests.

Intuitive programming mode does not require qualification.

Automatic generation of product connection scheme according to documentation or reference mark.

Option of big items distributed testing.

Option of plugged-in adaptor automatic detection.

Quality connection measurements (overall resistance measurement, phase angle measurement, power dispersion measurement and others).

Twisted-pair wire and coaxial cables testing. Detection of double transposition (changing of wires mutual disposition) and incorrect core screening.

Specification

1. Specification_RUS.docx